Sandpaper is one of the world’s most ubiquitous tools. It’s used in all types of projects, and it’s a crucial part of refinishing timber floors, decks and furniture.

There are dozens of varieties of sandpaper to choose from. The type of sandpaper you use can affect the quality of the final finish, so it’s important to understand what you’re working with.

In this article, we’ll explain how sandpaper is graded, and provide recommendations on which grit to use for sanding and refinishing timber floors.

How Sandpaper Works

Sandpaper is an abrasive tool that consists of a backing paper (or cloth and mesh) with abrasive material adhered to one side. It’s used to remove material from a surface. This can strip away paint, polyurethane and other coatings, and/or make the surface smoother.

How Sandpaper Grit is Measured

The abrasiveness of sandpaper is measured by its “grit”. Grit is a measure of how many of the abrasive particles can pass through a 1 square-inch filter. Therefore, the lower the number, the more abrasive the sandpaper is.

For example, 40 grit sandpaper is very coarse, while 800 grit sandpaper is very fine.

These abrasive particles are made from a variety of materials. The common ones include:

- Aluminium oxide – Aluminium oxide is the most common abrasive. It’s cheap and effective, but it wears out quickly. Suitable for soft materials like timber.

- Silicon carbide – Silicon carbide offers extra strength and longevity. It’s hard and best suited for materials like glass.

- Zirconia – Zirconia sandpapers offer excellent performance and longevity. They’re suitable for most types of soft and hard materials.

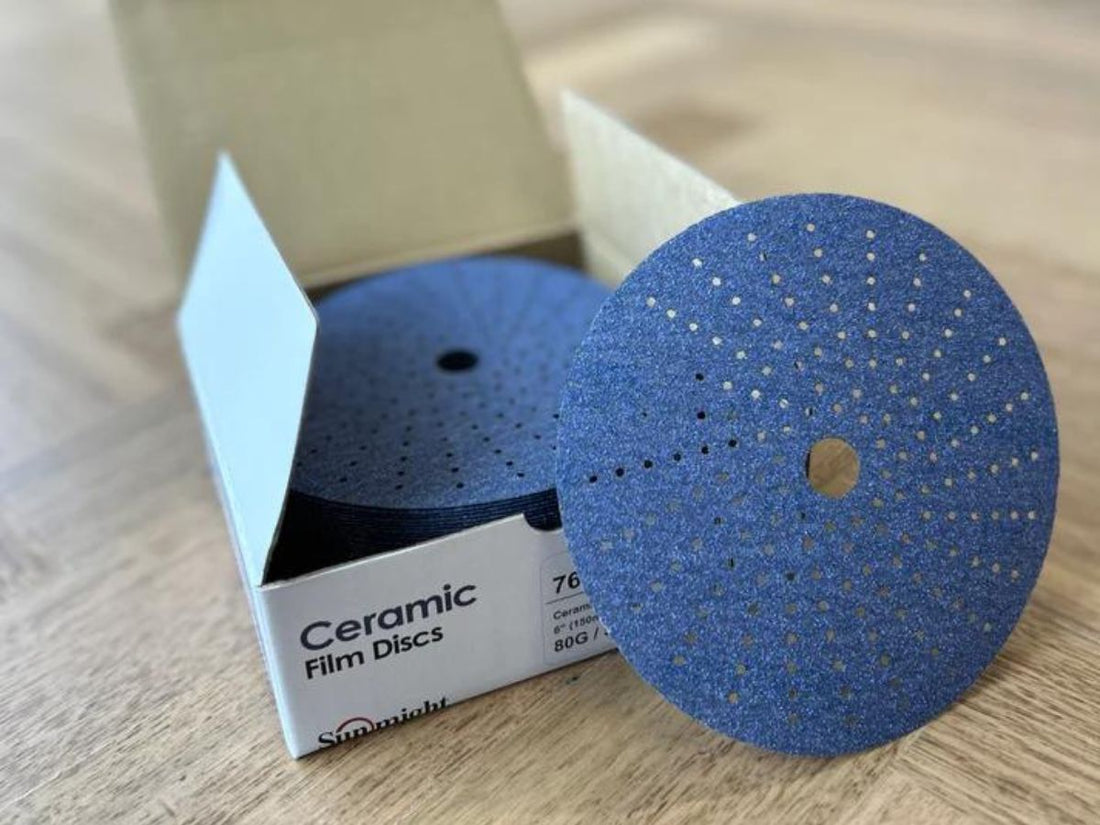

- Ceramic – Ceramic is the toughest and highest-performing abrasive for sandpaper. It resists dulling and build-ups of heat, which make it effective for all types of materials.

Ceramic sandpapers are some of the most effective abrasives on the market. The hardness of ceramic particles means the sandpaper lasts longer and that it’s resistant to heat. We recommend using ceramic sandpaper for tasks like refinishing timber floors with commercial machinery.

Sandpaper Grit vs Sandpaper Grade

Sandpaper grit is a measure of the size of the abrasive particles. Sandpaper grade is a description of the coarseness of the sandpaper. The grades run from extra coarse through to ultra fine.

When choosing sandpaper for your project, it’s usually more important to pay attention to the grade than the grit.

For example, we’d recommend using a coarse grade of sandpaper for the first pass when sanding an outdoor timber deck. It doesn’t matter whether you use 40 grit or 50 grit paper, as long as it’s somewhere in that range.

Choosing the Right Sandpaper for Your Project

Sandpaper is useful for removing material and coatings, refining shapes and finishing surfaces. The table below shows a rough guide on how each grade of sandpaper is commonly used:

|

Sandpaper Grade |

Sandpaper Grit |

Application |

|

Extra Coarse |

24-36 |

Stripping old finishes |

|

Coarse |

40-50 |

Bulk sanding, removing old finishes, removing imperfections, shaping wood (e.g. sanding sharp edges on furniture) |

|

Medium |

60-80 |

Removing minor imperfects in floors, removing thin coatings of paint |

|

Fine |

100-120 |

General sanding, prep for water based polyurethane and other wood finishes |

|

Very Fine |

150-220 |

Fine surface prep for penetrating wood oils |

|

Extra Fine |

320-360 |

Sanding between coats of wood treatment or paint |

|

Super Fine |

400-600 |

Sanding and polishing raw or finished timber, wet sanding certain types of timber finishes |

|

Ultra Fine |

800+ |

Sanding and polishing raw or finished timber, wet sanding certain types of timber finishes |

Still unsure which sandpaper grit to use? Watch this step-by-step guide to see exactly how to choose the right grit for your project.

Which Sandpaper Do I Need to Refinish Timber Floors?

If you’re using commercial equipment to sand your floors, we recommend using the following sandpaper grits:

- First pass – 40 grit

- Second pass – 60 grit

- Third pass – 80 grit

- Buffing – 100 to 120 grit

- Before final coat – 150 to 200 grit

You can use these grades of sandpaper for timber floors, decks and furniture.

Don’t throw away your worn-out sandpaper screens! Old screens are mostly smooth, making them good for polishing your floors in between coats of your chosen finish.

See our complete guide on refinishing your timber floors for more details.

A Note on Sanding Equipment

The type of sandpaper you choose also depends on the machinery you’re using. Commercial sanders that are used for refinishing timber floors require specific sizes of sanding pads and belts.

Tackle Your Next DIY Project With Quicksand Supplies!

Sanding and refinishing timber floors takes a little bit of elbow grease and a lot of sandpaper, but it’s something you can do yourself!

If you’re unsure where to start, Quicksand Supplies provides everything you need to sand your floors, decks and timber furniture.

We carry a range of sandpaper products that are compatible with commercial sanding machinery including hire machines. Our sandpaper discs and belts are sized to suit professional floor sanders and floor edgers. These can be hired from stores like Bunnings, and then you’ll have everything you need to refinish your floors.

For everyday cleaning after refinishing, check out our range of spray mops designed to care for timber floors without damaging your new finish.

Contact our team if you have any questions – we can provide advice on sandpaper, hiring equipment and the best floor coating systems for your timber floors and furniture.